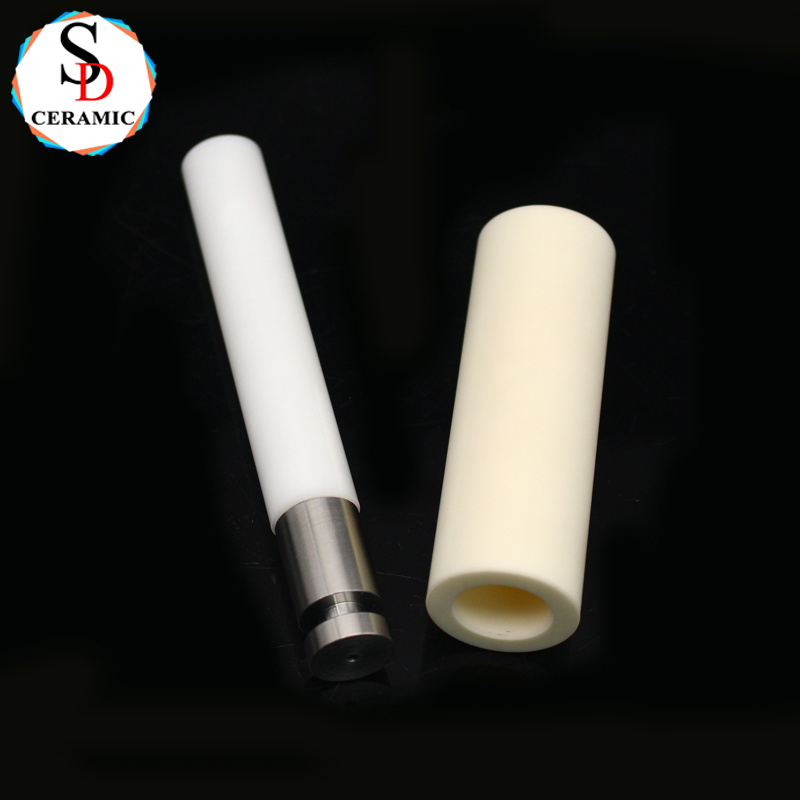

The ceramic materials of zirconia ceramic metallized products are divided into 99 white zirconia ceramics and 97 black zirconia ceramics, and the forming methods are isostatic pressing and dry pressing. The main type is metalized ceramic substrate, which can also be used as a metalized ceramic substrate. There are two metalization methods: thick film method and co firing method. The product has precise dimensions and small warpage; Strong bonding strength between metal and ceramic; The joint between metal and ceramic is dense, providing better heat dissipation. Can be used for LED heat dissipation substrates, ceramic packaging, electronic circuit substrates, etc.

Before metalization and sealing of ceramics, a spoonful of connected porcelain pieces should be treated according to certain requirements to achieve the requirements of no burrs or protrusions around the edges, smooth and clean porcelain pieces. After metallization and sealing, it is required that there are no silver layer points around the thickness of the porcelain piece.

The metalization and sealing of ceramics are achieved by coating a metal thin film with high conductivity and strong bonding on the surface of the working part of the ceramic as the electrode. When using this method to weld ceramics and metals together, the main process is as follows: metallization, sintering, infiltration, deposition of metal films on the surface of ceramics, heating of solder, and sealing of ceramics and metals.

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By