Shengda Ceramics can customize products according to customers' requirements.

Product Introduction

Precision Al2O3 Ceramic Machining Services for Industrial Applications

Our high-purity alumina ceramic (Al2O3) components are engineered for extreme environments, offering superior wear resistance, electrical insulation, and thermal stability up to 1750°C.

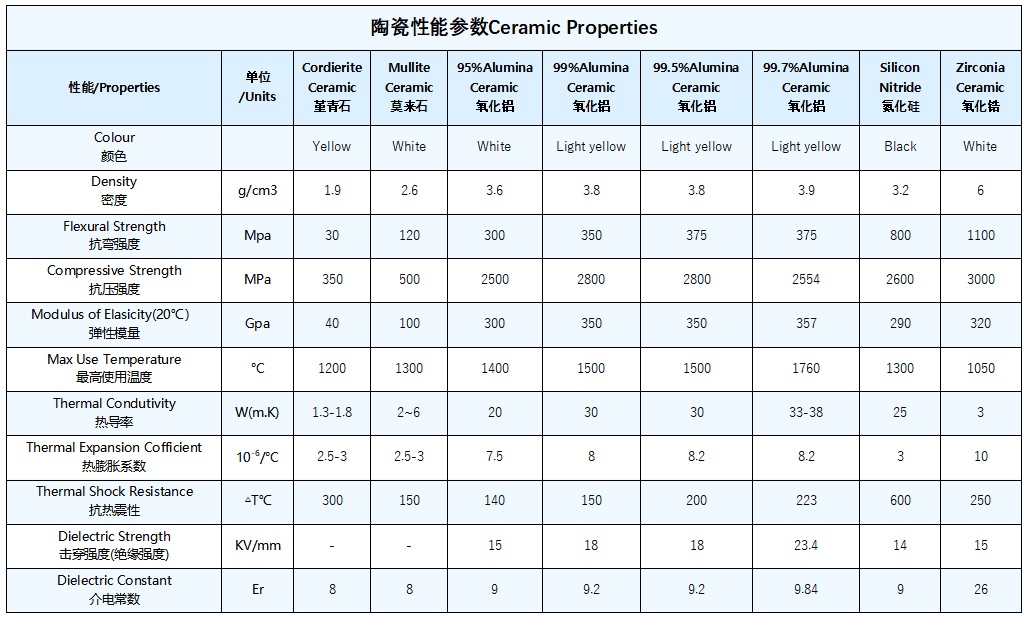

Key Technical Parameters:

▸ Material Grades: 95% Al2O3 (ISO 6474-1), 99% Al2O3, 99.5% Al2O3

▸ Density: 3.6-3.9 g/cm³

▸ Hardness: ≥82 HRA (Rockwell)

▸ Flexural Strength: 300-400 MPa

▸ Dielectric Strength: 15-20 kV/mm

▸ Surface Finish: Ra 0.1-0.4μm (mirror polishing available)

▸ Tolerance: ±0.01mm (CNC machining capability)

Industrial Application Cases

1、Semiconductor Wafer Handling

Problem: Plasma erosion of quartz components

Solution: 99.5% alumina ceramic arms with RF-transparent properties

Result: 8x longer service life vs. traditional materials

2、Medical Laser Components

Custom CO2 laser tubes with 0.05mm bore accuracy

Withstand 1500°C operating temperatures

Passed ISO 10993-5 cytotoxicity testing

3、Oil & Gas Valve Seats

95% Al2O3 parts for sour gas service

Zero corrosion in H2S environments

Reduced maintenance intervals by 70%

4、Automotive Sensor Housings

EMI-shielded alumina ceramic cases

Stable dielectric properties from -40°C to 850°C

Passed 1000hr salt spray testing

5、Food Processing Wear Plates

FDA-compliant ceramic liners

12x harder than stainless steel

Eliminated metal contamination

|  |

Main Features:

1. High hardness

2. High heat resistance

3. Good wear resistance

4. High electrical resistivity

5. High corrosion resistance

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : High Quality Custom Ceramics Al2O3 Ceramic Machining Ceramic Part

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By