Shengda Ceramic provide all kinds of ceramic part. Also can supply the mirror surface treatment to meet the sealing requirements of bearings, etc. Any dimension requirement, please contact us.

Product Introduction

Ultra-Stable Steatite Ceramic Terminal Blocks for Extreme Environments

High-Temp Wire Connection Blocks with 1500°C Resistance & Superior Dielectric Properties

Critical Performance Advantages

✔ Zero Thermal Degradation - Maintains >99% insulation resistance after 1000 thermal cycles (25°C⇄800°C)

✔ Corrosion Proof - Resists SO₂/H₂S gas exposure (tested per ASTM B809)

✔ Flame Retardant - UL94 V-0 certified (3mm thickness)

✔ Precision Molded - ±0.05mm dimensional tolerance for secure wire clamping

|

|

Industry-Proven Applications

Challenge: Polymer terminal blocks melting in battery overheating scenarios (>600°C)

Our Solution: Steatite ceramic blocks in BMW iX thermal runaway protection module

Result: Maintained circuit integrity during 15-minute 900°C fire test (ECE R100 certified)

Case Study: Replaced alumina connectors in steel annealing furnace control panels

Data: 3-year operation with <0.1% resistance drift vs. 8% drift in competitors' products

Application: 35kV busbar connections in offshore wind turbines

Performance: Withstood 100kA short-circuit current (0.2s duration per IEC 62271-1)

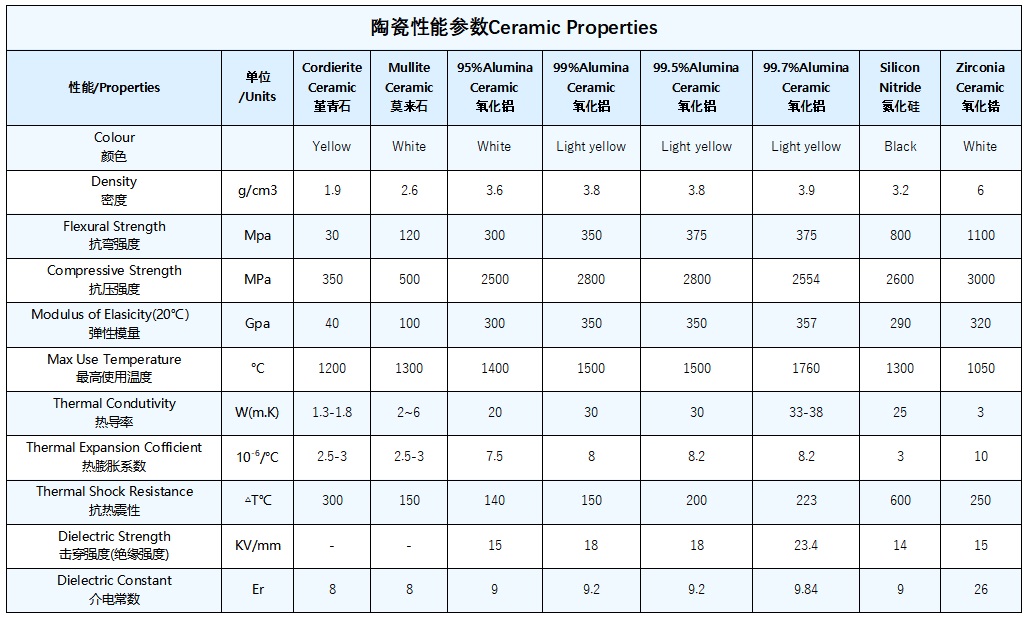

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Packaging and shipping

FAQ :

Q: How can I get the after-service?

A: Any quality problem, feel free to contact us, we’ll deal with it within 3 working days.

Q:What kind of transportation mode do you have?

A: By Sea/By Train/By Air or By Express, 15-20days Against Deposit.

Q: How is your price level?

A: Factory direct sale, we have whole production line work process from platform to main parts. We have hot injection machine and dry pressing machine.

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Steatite Ceramic Terminal Block Connector for Wire Connection

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By