Shengda Ceramic provide all kinds of alumina ceramic part. Also can supply the mirror surface treatment to meet the sealing requirements of bearings, etc. Any dimension requirement, please contact us.

Product Introduction

High-Performance 99% Alumina Tubes | Precision Small-Diameter Ceramic Tubing Solutions

Our 99% purity alumina ceramic tubes deliver exceptional thermal and mechanical performance for demanding industrial applications. These small-diameter ceramic tubes feature ultra-tight tolerances (±0.5%) and superior surface finishes for critical fluid handling and insulation systems.

Key Applications & Case Studies:

1. Semiconductor Processing Equipment

Our 3mm ID alumina tubes are widely used as gas injection liners in plasma etchers, demonstrating:

• 40% longer service life than standard 95% alumina tubes

• Zero particle generation after 500 thermal cycles (RT-400°C)

• Certified for use in Class 10 cleanrooms

2. Thermocouple Protection Sheaths

Case Study: In steel annealing furnaces (1250°C environment):

• Outlasted metallic sheaths 8:1 in lifespan testing

• Reduced temperature measurement lag by 35%

• Withstood 50+ rapid quench cycles (1250°C→RT)

3. Laboratory Reactor Liners

• Chemical resistance to all acids except HF and hot H₃PO₄

• Zero contamination in pharmaceutical synthesis applications

• 99.99% purity maintained after 100 batch processes

4. Fiber Optic Feedthroughs

• Optical transmission >85% in visible spectrum

• Hermetic sealing to 10⁻¹⁰ atm·cc/sec He leak rate

• MIL-STD-883 certified for defense applications

|  |

Why Choose Our Alumina Ceramic Tubes?

Main Features:

1. High hardness

2. High heat resistance

3. Good wear resistance

4. High electrical resistivity

5. High corrosion resistance

Performance:

1. The strong acid and alkali resistance of zirconia ceramic shall be better than other materials.

2. Zirconia ceramics are not easy to wear, with strong durability. The hardness is close to the natural diamond and light than metals, also has the gem properties such as never wear and non - discoloring.

3. Can maintain the mechanical strength under high temperature, can be used in the condition with high temperature.

4. Good surface finish quality, could get more glossy smooth surface. Small coefficient of wear, with quite good self - lubricating function, non - magnetic, electric insulation, static - free, anti interference and radiation.

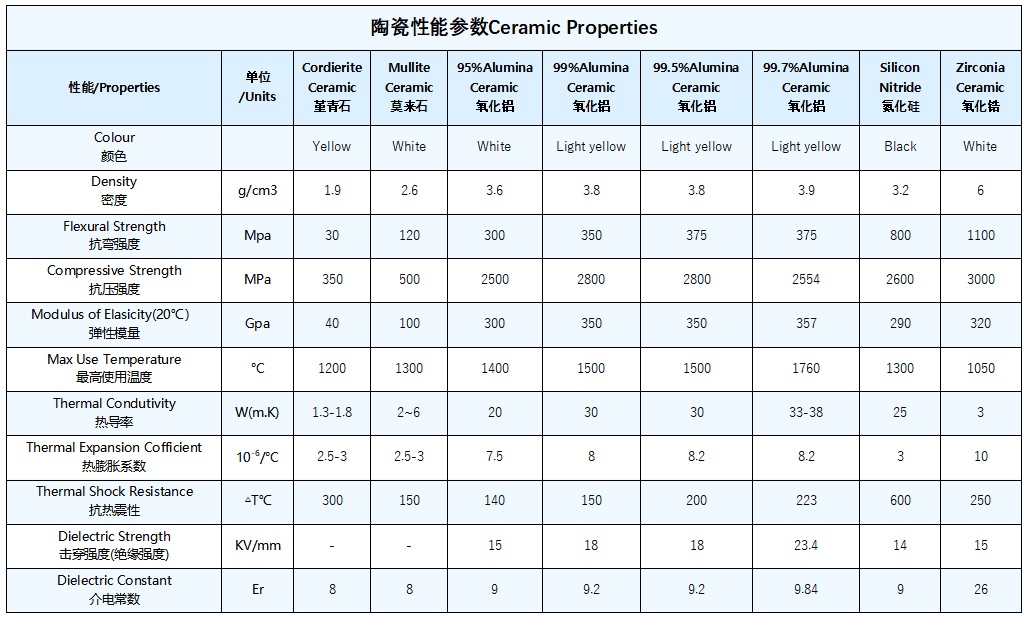

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : 99% Alumina Tubes Small Diam Alumina Ceramic Tubes

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By